Lapidary rough prices vary substantially depending on market supply and demand, with some types costing only a few dollars per pound and others reaching hundreds or thousands of dollars per pound.

Proper slabbing substantially increases the value of lapidary rough, yet numerous costs are still involved in producing lapidary slabs.

In addition to the equipment costs, diamond blades, oil, and electricity expenses, several other factors contribute to the overall costs of cutting lapidary slabs from rough.

No Guarantees

Experienced lapidarists can still be surprised, as rough materials with striking external features may sometimes produce slabs that are barely distinguishable from ordinary rocks. In such cases, the lapidary rough may be rendered completely unusable.

Prior to cutting, each piece of rough should be inspected to reduce waste and produce the most desirable outcome.

The lapidarist must factor in the saw blade’s size, imperfections in the rough, and material type when choosing the rough and planning the cutting strategy.

Loss of Lapidary Rough While Cutting

Material loss occurs during the cutting process due to the removal of rough ends and the thickness of the blade with each slab cut. Additionally, imperfect slabs may result from the cutting process, often due to incorrect thickness or angular cuts.

The material itself may exhibit imperfections like fractures, voids, or soft areas, thereby reducing the amount of usable material following the slabbing process.

Orientation of the Rough Can Produce different Results

Determining the optimal stone orientation for maximum results can be straightforward at times, yet more challenging on other occasions.

Turritella Agate

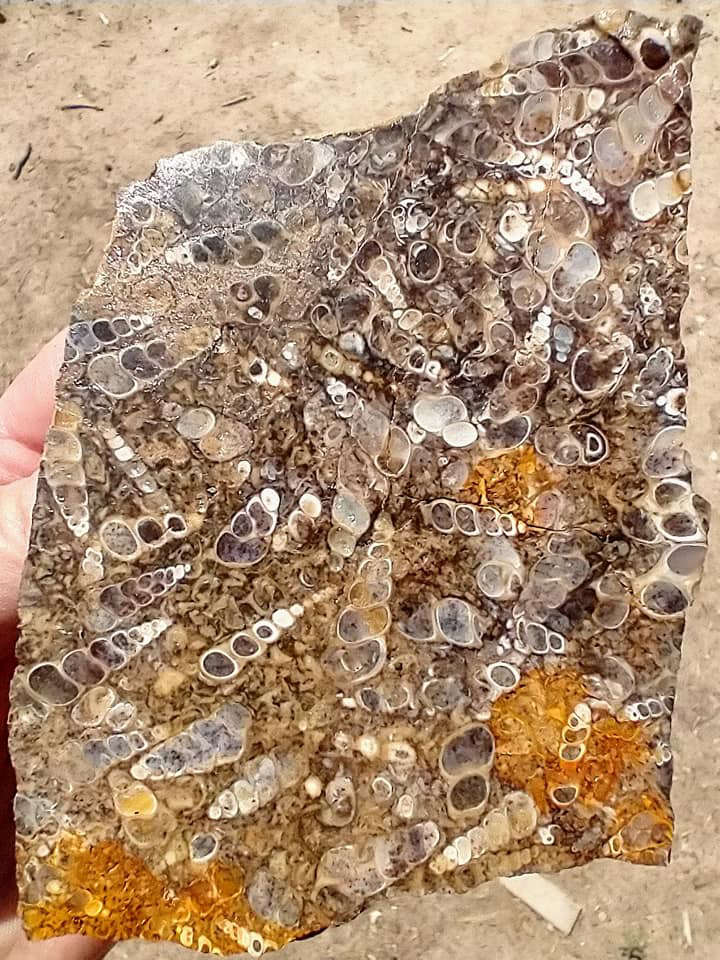

The specimen below is an example of Turritella Agate sourced from Wyoming, comprising the fossilized remains of Elimia tenera, a freshwater snail, rather than the marine snail Turritella.

By thoroughly inspecting the rough from every perspective, you can judge the most effective cutting technique to highlight the fossilized snails.

Upon side-view observation, the snails seem to be a fairly mundane assortment of slender, rounded shells that, although somewhat captivating, do not fully reveal the comprehensive ruggedness of their exterior.

When viewed from above, the snails’ orientation allows for a detailed observation of their shell shape, size, and spirals, offering a good indication of their potential appearance in a slab-cut format.

Upon closer examination of the rough material, two potential cutting options emerge. Cutting the slab parallel to the top surface or alternatively, cutting through the side. While cutting through the side presents the easiest and most efficient approach, yielding the maximum number of usable slabs, cutting parallel to the top surface, although more challenging and wasteful, would optimally showcase the aesthetic appeal of the embedded shells.

The Results

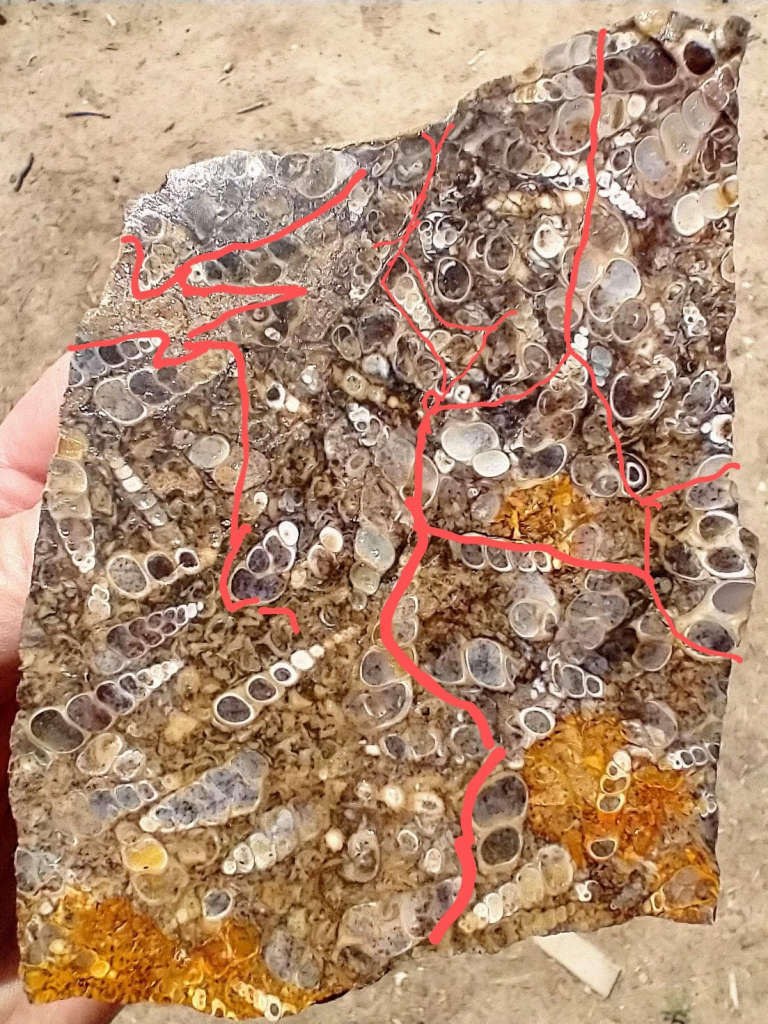

The resulting slab exhibited a desirable orientation of the shells within its structure. It was an aesthetically pleasing slab. However, upon more detailed inspection, the slab revealed numerous fractures.

This is a potential hazard when cutting lapidary rough, as the internal condition of the material cannot be precisely determined.

This slab will need to be broken down to the point where no fractures are visible prior to being cut into cabochons.

Despite the presence of multiple fractures in the slab, it is still expected to yield several high-quality cabochons.

Laguna Lace Agate

In certain situations, determining the optimal method to enhance the beauty and value of the slabs produced from cutting a piece of lapidary rough can be significantly more challenging.

The Laguna Lace Agate below, for example, features appealing patterns, although its color range is limited. To capitalize on the value of the resulting slabs, the material must be cut in a manner that emphasizes the stone’s internal patterns.

The stone’s top view displays a botryoidal surface, suggesting the presence of attractive patterns beneath the surface.

An inspection of the stone’s side reveals pleasing patterns, but they do not extend throughout the stone. Furthermore, an area populated with quartz crystals is discernible.

Regions containing quartz often exhibit instability and prone to fragmentation. Although these quartz-filled areas may appear solid, their solidity can only be accurately determined after the rock has been sliced into slabs.

Given the minimal color variation in this Laguna Lace agate, it is advisable to cut it in a way that maximizes the visibility of its patterns.

Cutting the stone parallel to its top surface would maximize pattern visibility, resulting in a limited number of slabs, but of superior quality.

The Results

When cut in this manner, it yielded three high-quality slabs that should be able to produce some exquisite cabochons.

A couple of slabs were noted to have a high waste content, but they are still expected to yield a couple of premium cabochons. Although the quartz area was largely unusable, a notable exception was a more solid and compact area.

The Advantage of Buying Lapidary Slabs

While buying lapidary slabs is more expensive than purchasing the rough and cutting it yourself, you avoid the costs of the equipment and risks associated with cutting lapidary rough.

Buying lapidary slabs is more expensive than purchasing rough and cutting it yourself, yet it negates the need for equipment investment and mitigates cutting risks.