The cost of lapidary rough can vary greatly depending on the supply and demand of the rough. Some rough can cost only a few dollars per pound while some rough can cost hundreds of even thousands of dollars per pound.

The value of the lapidary rough usually increases greatly once the rough has been properly slabbed. While the value goes up there are still a lot of costs associated with producing lapidary slabs.

Besides the cost of the equipment, diamond blades, oil, and the electricity it takes to cut the slabs there are several other factors that are costs associated with cutting lapidary slabs from rough.

No Guarantees

Even the most experienced Lapidarist gets surprised once and a while. Rough that looks amazing on the outside can sometimes produce slabs that aren’t much better than yard rocks.

When this happens the lapidary rough can be a total loss.

Each piece of rough should be inspected prior to cutting to produce the least amount of waste and/or get the most beautiful results.

The size of the saw blade is one of the limitations that the lapidarist must consider when choosing the rough and how it will be cut. Other factors include the imperfections in the rough itself and the type of material.

Loss of Lapidary Rough While Cutting

Material is lost in the cutting process itself. The ends of the rough are cut off when the rough is cut and the thickness of the blade is lost each time a slab is cut. During the cutting process, there are also often slabs that are imperfect and maybe cut too thick, too thin, or at an angle.

Slabs may have imperfections from the material itself such as fractures, voids, or soft areas that reduce the amount of usable material once the rough is slabbed.

Orientation of the Rough Can Produce different Results

Sometimes it’s quite easy to tell how the stone should be oriented in order to get the best results and sometimes it’s a little more difficult.

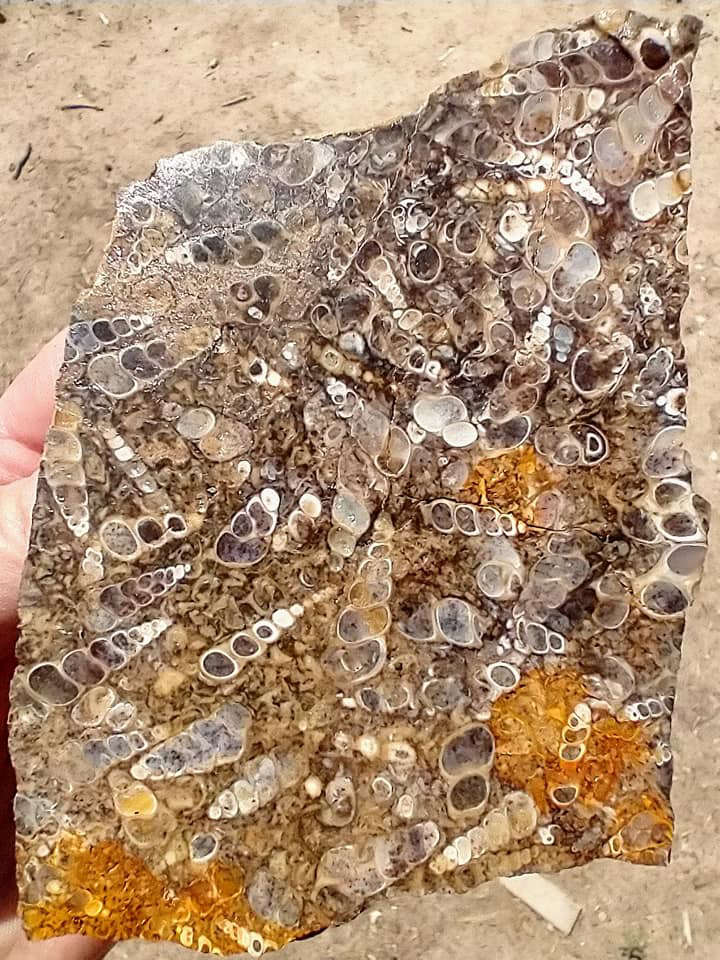

Turritella Agate

Below is an example of a piece of Turritella Agate from Wyoming. Turritella Agate is the fossilized remains of Elimia tenera, a freshwater snail, and not the remains of Turritella which are marine snails.

By looking at the rough from all sides you can judge how the rough should be cut in order to best show off the fossilized snails.

Viewed from the side, the snails appear as a rather mundane group of thin round shells that are interesting but don’t really show the full potential of the rough.

Viewed from the top, the snails are oriented in a manner that the shape, size, and spirals of the snail shells can be seen. Although you can’t see what they might look like cut into slabs it gives a good indication as to what it might look like.

Looking at the top of the rough it looks like there could be two possibilities for cutting it. The slab could cut parallel to the top surface or it could cut on the side where you can see it would cut through the most shells long ways. Unfortunately looking at the sides I found that all four sides looked the same with just round circles showing.

When cutting this rough I would cut it parallel to the top surface of the rough to expose the maximum beauty of the shells within.

Unfortunately Turritella Agate rough usually comes in somewhat thin layers. When this piece is cut for maximum beauty it will also produce the most waste.

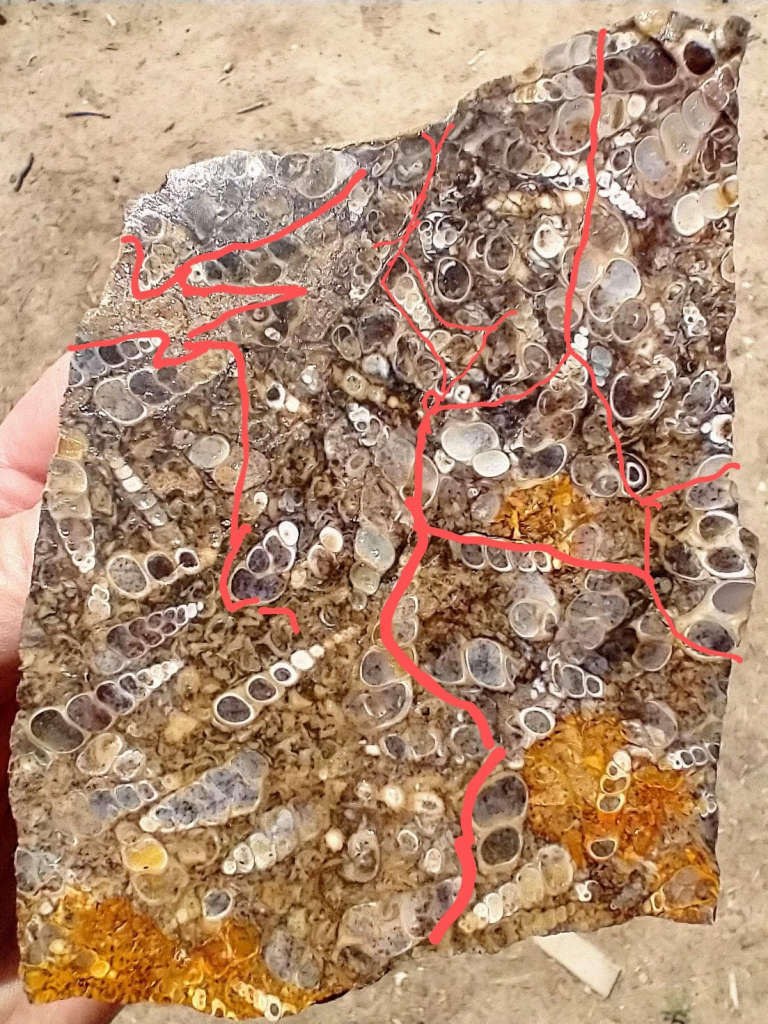

The Results

The resulting slab showed a nice orientation of the shells within the slab. It was a good-looking slab. Unfortunately, upon a closer examination, the slab had numerous fractures in it.

This is one of the risks when cutting lapidary rough. You never know exactly what condition the inside of the material is going to look like.

Unfortunately, this slab will have to be broken up to the point that there are no more fractures before cutting it into cabochons.

Although there are multiple fractures in the slab it still should produce several nice cabochons.

Laguna Lace Agate

In some cases, it can be much harder to decide how to maximize the beauty and value of the slabs that are produced when cutting a piece of lapidary rough.

For example, the Laguna Lace Agate below has some very nice patterns but it isn’t very colorful. To maximize the value of the slabs produced the material should be cut in a way as to show off the beautiful patterns that are within the stone.

The top view of the stone shows a nice botryoidal surface indicating that there may be some beautiful patterns just below the surface of the stone.

Examining the side of the stone I can see that there are some nice patterns however it doesn’t go all through the stone. There is also an area that is filled with quartz crystals.

These areas filled with quartz are often unstable and break apart easily. The quartz-filled areas may be solid however It’s difficult to tell how solid it will be until the rock is cut into slabs.

Because this piece of Laguna Lace agate has very little color differentiation it should be cut it in a manner that will show off the patterns as much as possible.

To maximize the patterns within the stone it could be cut parallel to the top surface. This would only produced a couple of slabs but they should be nice.

The Results

When cut in this manner it produced three nice slabs that should be able to produce some nice cabochons.

There was also couple of slabs that will have a lot of waste but should be able to produce a couple of nice cabochons out of them. The quartz area was mostly unusable but there was a nice area that was more solid.

The Advantage of Buying Lapidary Slabs

While buying lapidary slabs is more expensive than purchasing the rough and cutting it yourself, you avoid the costs of the equipment and risks associated with cutting lapidary rough.

When buying lapidary slabs rather than rough, someone else has taken most of the risk out of the purchase. The buyer gets a much better idea of what the material is like and what the finished product might look like.